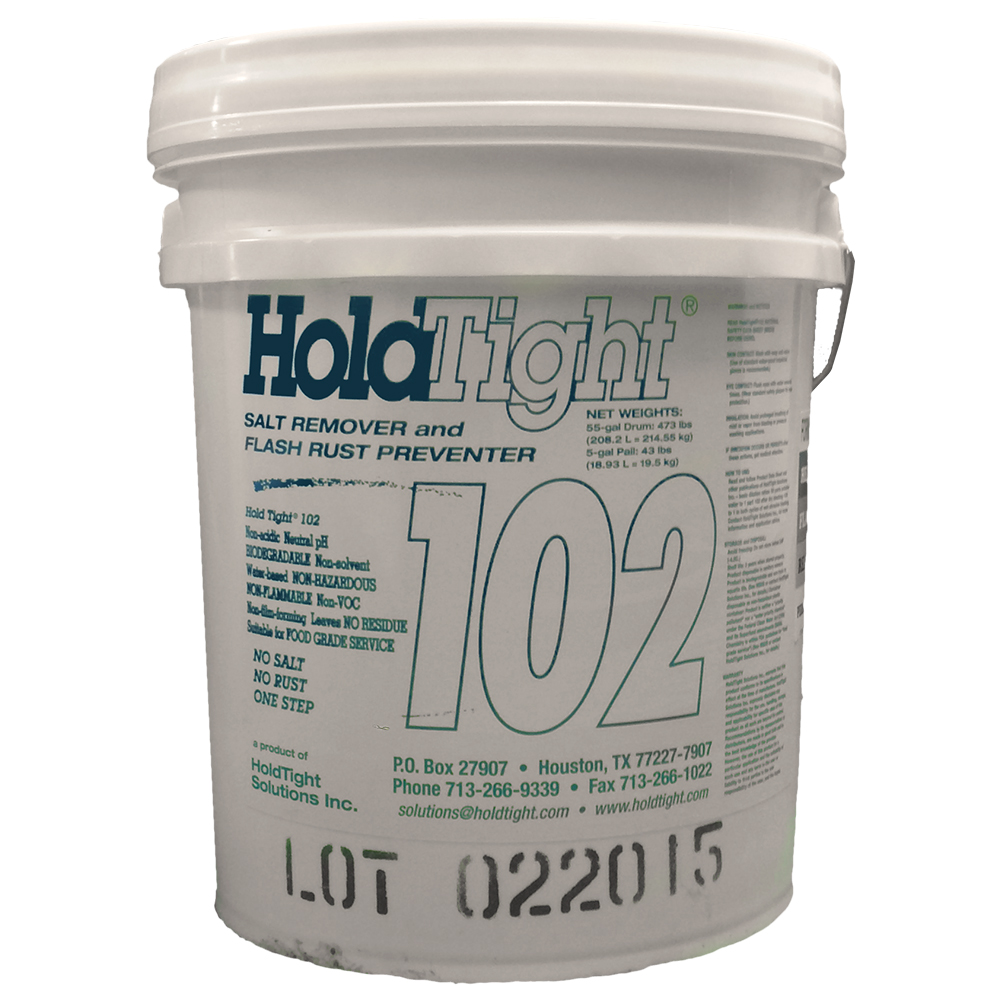

No salt. No rust. One step.

HoldTight®102 salt remover / flash rust preventer has set the standard of performance for more than a decade.

- Kills all salts

- Stops flash rust in one pass

- Leaves no residue

- Excellent for coatings

HoldTight®102 is the industry standard. Period.

Product/Safety Data

Get The Most out of HoldTight®

HoldTight® is as safe and simple to use as it is effective. To help you and your crew get the most value, we’ve provided several helpful resources below on how to properly mix, apply and dispose of HoldTight® during your next project.

Description

Product Overview

Superior Surface Prep for a Superior Lifetime Value

Protect your next project with HoldTight® 102 – the ultimate surface prep solution. Reduce the costs of maintenance, re-painting and surface preparation when you use the industry’s most proven salt remover / flash rust preventer. Our unique solution has set the standard of performance for more than a decade. It removes all salts and prevents flash rust in one pass and leaves no residue.

HoldTight® is a simple, one-step solution that leaves you with the cleanest possible surface. It effectively removes surface contamination, salts and light oils and greases, and evaporates with the water leaving a surface clean and ready to finish. Spraying water mixed with HoldTight® prior to coating application removes both naturally occurring contaminants (salts, acids), and byproducts of the blasting process (shattered abrasives, dried paint), allowing for the most adhesive coatings with zero residue or flash rust left behind.

HoldTight® is a safe and effective cleaner for surfaces that delivers superior surface preparation with proven results on land, at sea, on storage tanks, on oil rigs and even in specialty projects like restoring vintage cars. The cleanest surfaces with the least likelihood of flash rusting within 48 to 96 hours (as determined with the fewest or no detectable contaminants, including salts) are achieved when the product is used in both the blast and wash down cycles at a 50 to one, water to HoldTight® 102, ratio. HoldTight® is the only choice to extend the life and value of your assets for just pennies per application.

[accordion title=”Discover how HoldTight® is the BEST SOLUTION for your industry:”] [accordion-item title=”Marine”]The only solution you need.

Protect and renew in one simple step.

100% water soluble and environmentally friendly.

Protecting marine vessels can be a complicated process. HoldTight® helps you keep things simple, efficient and cost effective.

HoldTight® protects your ships, FPSOs, tugboats and other marine vessels from salt and flash rust, leaving behind zero residue in the process. Simply add HoldTight® 102 to water during wet abrasive or ultra-high pressure blasting, and spray for immediate results.

From workboats to ferries, you can rely on HoldTight® to protect what counts…even in the toughest of circumstances.

[/accordion-item] [accordion-item title=”Offshore”]A Simple Solution with Superior Results.

Trusted by major oil and gas corporations world-wide.

100% water soluble and environmentally friendly.

Protecting offshore equipment can be a complicated process. HoldTight® helps you keep things simple, efficient and cost effective.

HoldTight® protects your underwater pipelines and offshore rigs from salt and flash rust, leaving behind zero residue in the process. Simply add HoldTight® 102 to water during wet abrasive or ultra-high pressure blasting, and spray for immediate results.

Rest assured, you can rely on HoldTight® to protect what counts…even in the toughest of circumstances.

[/accordion-item] [accordion-item title=”Industrial”]Maximum Cleaning Power, Lasting Results.

Works on concrete, steel, aluminum, fiberglass and composites.

Perfect for lead abatement.

Easily incorporated into soda blasting process.

No other solution restores and resurfaces aging structures as efficiently and effectively as HoldTight®. Remove salt, lead and other contaminants from nearly any surface, including concrete, steel and fiberglass with zero residue left behind!

HoldTight® is safe to use in any setting. It has a proven track record of endurance in the field, preventing coat failure for as long as 10 years!

HoldTight® is simple and efficient to use. Easily incorporate HoldTight® into wet abrasive, ultra-high pressure and soda blasting processes in just one simple step, with no need for supplemental products.

[/accordion-item] [accordion-item title=”Infrastructure”]Restore, Renew and Protect…in one Simple Step.

Extends the life of nearly any paint job.

100% environmentally friendly.

Protect and renew in one simple step.

HoldTight’s® unique cleaning power is perfect for projects both big and small. When it comes to heavy-duty restoration tasks, HoldTight® 102 can prepare even the most tarnished surfaces for a new coat, and a new life.

HoldTight 102 has been used to prepare and protect surfaces ranging from tarnished bridges to inland water towers and beyond. No matter the job, HoldTight® is remarkably simple to use, and can be conveniently worked into any wet abrasive, ultra-high pressure or soda blasting process. In just one pass, HoldTight® delivers an exceptionally clean surface removing all contaminants with no unwanted residue left behind.

[/accordion-item] [/accordion]FAQ

[accordion title=”Coverage”] [accordion-item title=”Q: How Do You Apply HoldTight®?”]A: HoldTight®102 is not a coating. It performs its two principal functions – salt removal and flash rust prevention — as an adjunct to and enhancement of pressure washing with water (and/or wet abrasive blasting, or “wet jet” blasting, or “water jetting”). Thus, the question “How much ‘102’ must I apply to a given area?” is irrelevant. The relevant, and indeed only meaningful question is, “How much water will I use when I blast and/or pressure wash a specific area, given the equipment I am using (specifically, water consumption in a given amount of time) and the “production rate” (specifically, how much surface area do I cover in a given amount of time)?” The answer to that question determines how much of the product will be required. In short: determine how much water you will use based on flow rate, production rate, and the surface area, then divide by the dilution ratio you have chosen: 50, 100, etc. (Different flow and production rates will apply, of course, when water is used as part of the stripping process in wet-abrasive blasting. In such cases 102 must be used both in the stripping or removal operation and in the wash down operation.)

WITH REGARD TO WASHING DOWN SURFACES AFTER DRY OR WET-ABRASIVE ABRASIVE BLASTING —

We know from experience that 102-treated water applied at flow rates of less than 1 gpm under less than 500 psi at the surface is not sufficient to remove all abrasive dust, shattered corrosion products, and tiny paint particles, even when the surface has been “blown” clean with air only. (In fact, “blowing” a surface clean of dust generated by the abrasive blasting operation may result in adding contaminants to the surface from the compressor.) When such contaminants remain on the surface, flash rusting will occur.

We also know from experience that the cleanest surfaces are achieved with 102-treated water over 500 p.s.i. at 2-3 g.p.m. In most cases 2 g.p.m. at 1,500 p.s.i., or higher, will achieve the best results. At these recommended flow rates and pressures operator productivity is simply not a critical factor. The water flow and pressure, NOT the “dwell time”, are the determining factors (the “controlling variables”) so long as the water is treated with 102. If the operator, in those cases, moves the wash wand or tip very quickly over the entire targeted surface, he will use less HoldTight®102 without jeopardizing surface cleanliness. If he moves slowly, he will use more HoldTight®102, but will achieve the same result. Based on experience reported to us by many customers, these operations typically “clean” 500 to 1,000 square feet per hour. (Production rate is of course a function of operator skill and strength, surface flatness vs. surface irregularities, and constraints imposed by positioning equipment, scaffolding, lifts, etc.)

If the water does not contain HoldTight®102 in the recommended ratio the surfaces will flash. If the water is significantly substandard (in terms of chlorides or other contaminants and/or carbonates [hardness]) as discussed in our literature on the subject, the surfaces might “flash” or “turn” even with 102 (or, for that matter, any additive that purports to remove contaminants). In such cases, either increasing the 102 to water ratio or pre-treating the water, or some combination of both, will be necessary.

[/accordion-item] [accordion-item title=”Q. How long will the surface remain rust-free after cleaning with 102?”]A. Until wetted with water, most typically by rain, OR until re-contaminated by airborne particles or ionic contaminants, which will draw moisture out of the air, the surface should remain rust-free. Outdoors this means 2 to 4 days. In extremely humid environments the rust-free period will be shortened; in extremely dry environments, it will be extended. Condensation forming on the surface as a result of rapid temperature changes my cause a 102- cleaned surface to flash rust, especially if the condensation is extensive enough to “pool” on a flat surface or run down a vertical surface. If held indoors, the rust-free window for the blasted surface should be much larger – even a month or more.

[/accordion-item] [accordion-item title=”Q. Will the use of Holdtight® 102 interfere with coating adhesion?”]A. When used properly, HoldTight®102 will leave no residue that would interfere with any coating or lining. In addition, many coating manufacturers have tested 102 used before applying their products. Most have approved 102 for use with all of their coatings on the basis of tests and/or field experience with 102 over many years. Much of that data is available. Request our “compatibility” chart for examples.

Also see our documents: “HoldTight®102 is not a coating; it is NOT applied”, “HoldTight®102 is like soap — but it is not soap”, “Coverage and HoldTight®102” and the Product Data Sheet for HoldTight®102.

[/accordion-item] [/accordion] [accordion title=”Disposal”] [accordion-item title=”Q: How Do I Dispose of HoldTight®?”]A: A number of studies of the proprietary compound that is the active ingredient in HoldTight®102 salt remover / flash rust inhibitor have concluded that the material may be safely disposed of in sanitary sewers, rivers, lakes, and other bodies of water without endangering aquatic life or otherwise compromising the environment. This was true even when that compound was tested at a much higher level of concentration than in HoldTight®102 on -the-shelf and dramatically higher concentrations than in the product as applied. The concentration of the compound in these studies was greater by a factor of 3 or 4 than its concentration in undiluted (“o -the- shelf”) HoldTight®102 and 150 to almost 1,000 times greater than in HoldTight®102 when it is used in ANY application. Even in these substantially higher concentrations, there were no measurable adverse effects.

NOTE:

When contamination levels are low (i.e., when the surface is relatively clean) after wet/vapor abrasive blasting and/or ambient humidity is relatively low, 1500 psi + pressure washing, though preferable, may not be necessary. This is true ONLY if the surface is surface is thoroughly rinsed at lower pressures with 102-treated water immediately after the wet/vapor abrasive blast cycle – preferably before the surface dries.

A: 102 has no VOCs. ND on the MSDS means “None Detected” or “Not Detected”, NOT “Not Determined”. Per our formulation and dilution ratios there are no VOCs.

[/accordion-item] [accordion-item title=”Q: What Level of Water Quality is Recommended When Using HoldTight®?”]A: HoldTight 102 recommends using potable water for its dilution. If potable water is not available and other water is used then the contaminant level needs to regulated for Total Hardness,

CHLORIDES AND PH LISTED BELOW:

1. Total Hardness < 120 ppm 2. Chlorides < 200 ppm 3. pH between 6.5 – 7.5 Before dilution with HoldTight® 102, water treatment can be used to regulate the levels. Various ion exchange resin units are available to soften the water. Reverse osmosis process can also be used to treat the water along with desalination which will regulate the pH and chloride levels. Some commonly used water treatment devices are available from Culligan and US Water Filter which can be delivered to the jobsite and installed directly in-line before the dilution step. [/accordion-item] [accordion-item title="Q: What is the lowest dilution limit when using HoldTight®?"] A: Increase in HoldTight® concentrations will only be effective to its saturation point (~25:1) where it will combat the high level chlorides. After the saturation point, increase in concentration will not help with chlorides but will slow down the evaporation of excessive HoldTight® on the surface that could lead to low levels of residue which may cause staining or spotting. [/accordion-item] [/accordion] HoldTight is not a Coating Tech Facts Disposal Product content courtesy of HoldTight.com